Which Best Reflects a System of Handling Workplace Hazards

Chemical hazards - Hazards stemming from any hazardous chemical. Entry restrictions prevent people from entering areas where pesticides have been applied.

How Can Occupational Safety And Health Be Managed Labour Administration And Inspection

Poorly stacked or stored loads and structurally damaged storage rack.

. Companies can provide training and equipment such as moving carts to help prevent this hazard. Blood or other bodily fluids bacteria and viruses insect bites and animal and bird droppings are all considered biological hazards. The efficient handling and storing of materials are vital to industry.

Poor floor or lot conditions. Repetitive or heavy lifting can be a workplace hazard. Identify and find things which have the potential to cause harm these can include.

Hazards frequently identified by the consultants include tasks related to working at height chemicals housekeeping electrical forklifts lockouttagout and confined spaces. You should summon medical personnel immediately in case of pesticide exposure. However proper air circulation can help eliminate the contaminants that lead to health problems.

In addition to raw materials these operations provide a continuous flow of parts and assemblies through the workplace and ensure that materials are available when needed. A WHMIS program ensures that the information about hazardous products is effectively communicated to workers. Falls slips trips and injuries from equipment all fall under this category.

The nature of health and safety systems operating in NZ workplaces how health and safety representatives operate in workplaces and how managers and employees interact with regard to health and safety how these systems and processes are influenced by the size of the workplace nature of industry and organisational form. It may also make you work in awkward positions to see clearly what you are doing. Short Confined spaces Machinery-related hazards lockouttagout boiler safety.

Some common chemicals you might have in your facility are. Insect and Pest Control Products. Physical risks are one of the most common hazards in the workplace.

It is a comprehensive system for providing health and safety information on hazardous products intended for use handling or storage in Canadian workplaces. These can be experienced in short term stress or long term strain that is associated with workplace issues such as workload lack of control andor respect etc. Examples of some common material handling hazards include.

Damaged or broken pallets. WHMIS stands for the Workplace Hazardous Materials Information System. Air circulation plays a key role in air quality.

Another potential danger of poor air circulation in a. Step 1 - Identify hazards -. The Manual handling operations or procedures can cause a wide range of the acute and the chronic injuries to the workers.

With manual handling in the workplace hard to hold tools requiring more force. Loads beyond the rated capacity of the forklifts. Cold can make your hands numb making it hard to grip7 Lighting Insufficient lighting may increase the risk of accidents when handling loads.

Respect or lack of. WHMIS requires three things on hazardous materials that are being used in the workplace. Common ergonomic hazards can include.

Its important to keep lids on containers at all times label hazardous waste as such and keep all materials properly stored. Review how hazardous materials are stored used and handled at your organization and make any changes needed to bring. Missing or non-functioning safety devices such as horns seat-belts alarms and strobes.

Biological hazards - Bacteria viruses animals other humans. Radiation is another prevalent type of hazard in the workplace. Hazards that are not as obvious include exposure to loud noises damaging lights radiation vibrations and working in and around extreme temperatures.

Best practices for storage areas recommend a dry cool storage area with adequate ventilation. Parasitic worms and some plants are biological agents. Here are work organization hazards examples.

Without proper circulation irritants remain in the air. Guards removed or moving parts that a worker can accidentally touch Electrical hazards like frayed cords missing ground pins improper wiring or the harm that these hazards pose. Unfortunately the improper handling and storing of materials often result in costly injuries.

Steps to help avoid potential tragedies caused by common hazards include providing appropriate employee training and equipment and instilling a positive culture of safety. These are also called biological agents and they can cause illnesses and diseases in humans. Anxiety stems from a wide range of issues such as concerns over job security age health training and new equipment as well as changes in schedules salary cuts and harassment.

The lifting sharp-edged or the hot loads that result in hand injuries. FlexibilityControl or say about things. Hard hats and safety boots safety glasses and dust masks suitable protective gloves and hearing protection.

At the same time exhaust systems and chimneys should also be kept free from anything that may block the vent system from operating. The poor posture during the lifting operation or poor lifting techniques or methods resulting in back injury. Sitting for a long time such as in an office role can become an ergonomic risk.

Ergonomic hazards - Repetitive movements incorrect posture incorrect set up of work environment. Ad Take Your Respectful Remote Workplace Training from Boring to Brilliant. In case of an emergency from a gas explosion employees should also be aware of which number to call for immediate relief.

While your supervisor or fellow workers may have information about a pesticide the best source of information is the pesticide label or MSDS. Emotional and Psychological Stressors Are Among the Top Hazards in the Workplace Make sure to include emotional and psychological well-being in your risk reviews. This workplace hazard is when there are solid liquid and gas chemicals used in the work environment with risks of exposure.

Typical hazards of manual handling include. Raised work area Unguarded machinery and moving machinery parts.

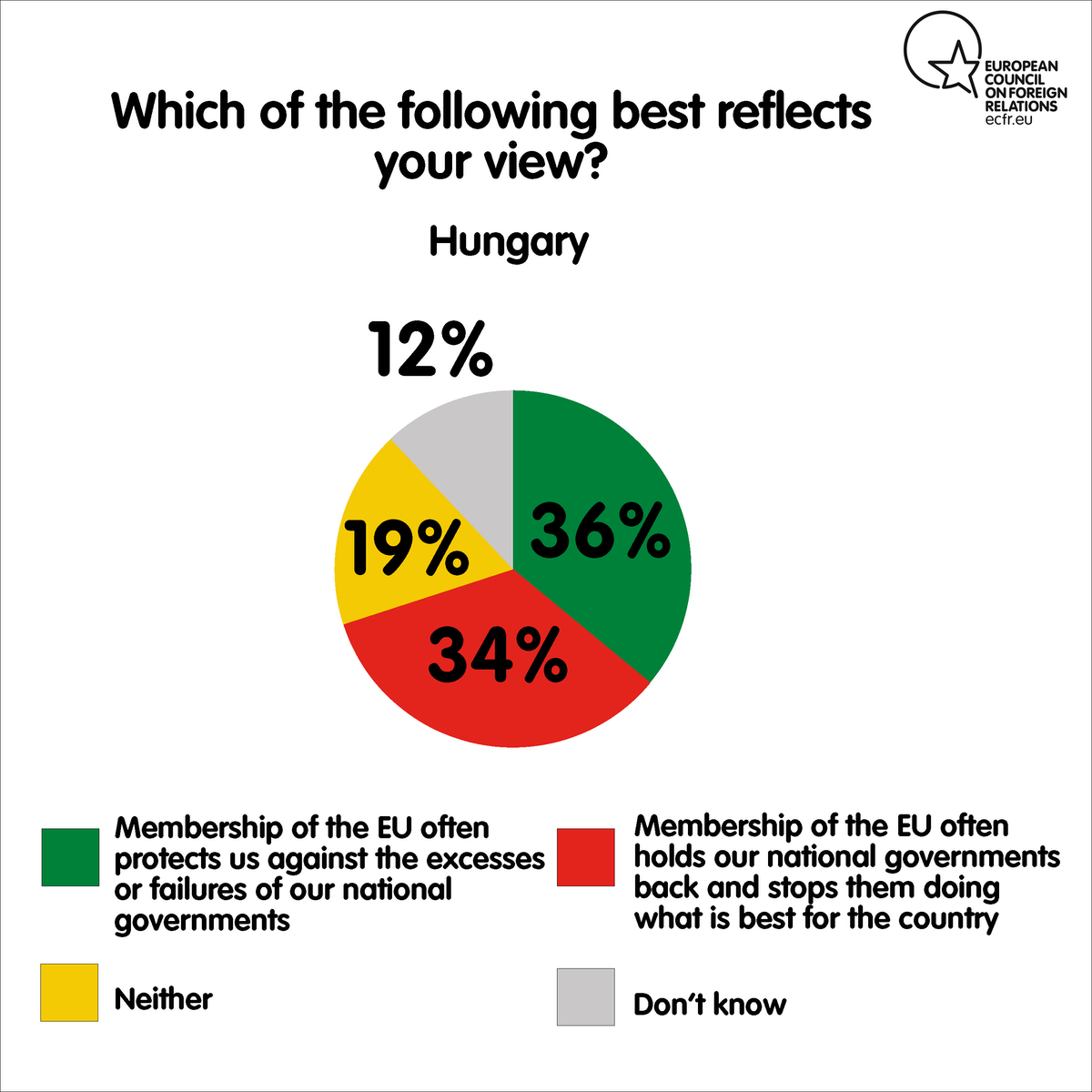

What Europeans Really Want Five Myths Debunked European Council On Foreign Relations

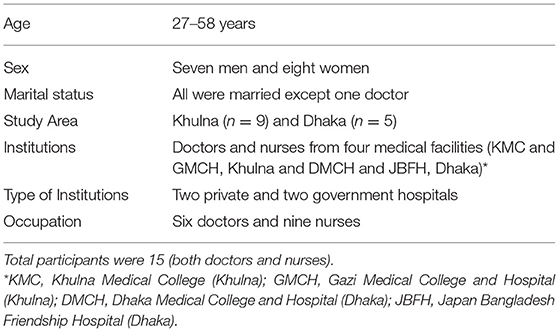

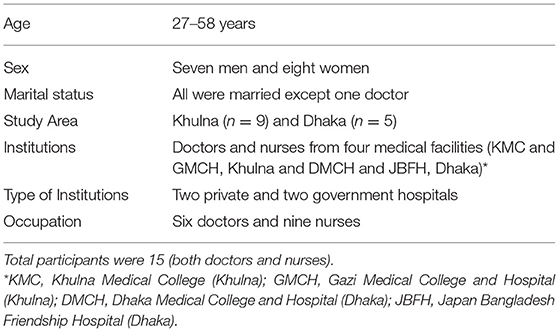

Frontiers Challenges Faced By Healthcare Professionals During The Covid 19 Pandemic A Qualitative Inquiry From Bangladesh Public Health

Comments

Post a Comment